Publications

The lab has moved to Carnegie Mellon University. Please visit:

https://www.meche.engineering.cmu.edu/faculty/panat.html

https://advancedmanufacturing.us/

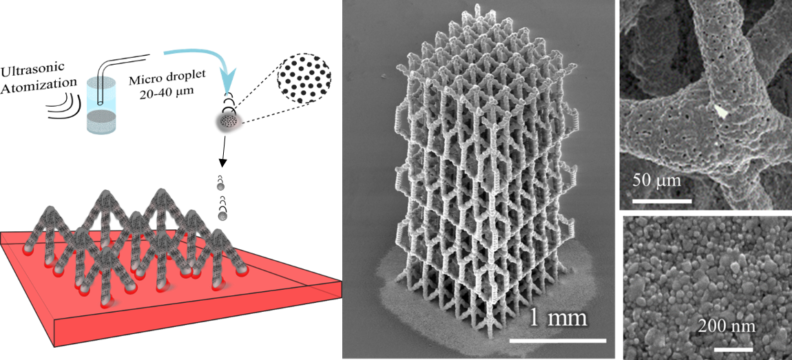

30. M. Sadeq Saleh, C. Hu, and R. Panat, “Three Dimensional Micro-architected Materials and Devices using Nanoparticle Assembly by Pointwise Spatial Printing”, Science Advances, 3, e1601986, 2017. PDF http://dx.doi.org/10.1126/sciadv.1601986

News in Media:

WSU News: https://news.wsu.edu/2017/03/03/novel-3-d-manufacturing/

Most comprehensive report was in German Media! (use right click and translate to english): Huge Nanostructures

I4U News: Researchers 3D Print Lightweight But Ultra-Strong New Material Like Wood And Bone

Materials Today: Novel 3D printing method goes up and down the scale

3-D Printing Industry: “Groundbreaking advance” in nanoparticle 3D printing mimics natural construction in the desert

Science Daily: https://www.sciencedaily.com/releases/2017/03/170303143221.htm

Yahoo News: https://sg.news.yahoo.com/scientists-create-ultra-light-super-190700874.html

Physics.org: https://phys.org/news/2017-03-d-highly-complex-bio-like-materials.html

The Independent UK: http://www.independent.co.uk/news/science/silver-nanotechnology-material-bone-wood-nature-desert-rose-washington-state-university-a7610376.html

Nanowerk: http://www.nanowerk.com/nanotechnology-news/newsid=45999.php

AZO Materials: http://www.azom.com/news.aspx?newsID=47328

New Atlas: http://newatlas.com/aerosol-jet-3d-printing/48267/

Swedish media: http://www.svt.se/nyheter/vetenskap/3d-teknik-skapar-supermaterial

Eurekalert: https://www.eurekalert.org/pub_releases/2017-03/wsu-n3m022317.php

FactorTech: http://factor-tech.com/feature/will-fan-made-games-ever-get-the-credit-they-deserve/

29. R. Sun, H. Yang, M. Rock, R. Danaei, R. Panat, M. Kessler, and L. Li, “Manufacturing PDMS Micro Lens Array using Spin Coating under a Multiphase System”, Journal of Micromechanics and Microengineering, Vol. 27(5), pp.1, 2017. PDF

doi: https://doi.org/10.1088/1361-6439/aa68c8

28. M. T. Rahman, J. Gomez, K. Mireles, P. Wo, J. Marcial, M. Kessler, J. McCloy, C. Ramana, and R. Panat, “High temperature physical and chemical stability and oxidation reaction kinetics of Ni-Cr nanoparticles”, Journal of Physical Chemistry – C, Vol.121 (7), pp. 4018–4028, 2017. PDF Link,

27. J. Geng, M. T. Rahman, R. Panat, and L. Li, “Self-assembled Axisymmetric Microscale Periodic Wrinkles on Elastomer Fibers”, ASME Journal of Micro and Nano-manufacturing, Vol. 5, Issue 2, pp. 021006, 2017. PDF

http://dx.doi.org/10.1115/1.4036112

26. J. Li, M. Leu, R. Panat and J. Park, “A Hybrid Three-Dimensionally Structured Electrode for Lithium-ion Batteries via 3D Printing”, Materials and Design, Vol. 119, pp. 417-424, 2017. PDF

http://dx.doi.org/10.1016/j.matdes.2017.01.088

25. Brian Paul, Rahul Panat, Christina Mastrangelo, and David Kim, and David Johnson “Manufacturing of Smart Goods: Current State, Future Potential, and Research Recommendations”, ASME Journal of Micro and Nano-manufacturing, Vol. 4, Issue 4, pp. 044001-1 to 044001-12, 2016. PDF

http://dx.doi.org/10.1115/1.4033968.

Also published as an NSF Workshop Report. PDF

24. Y. Arafat, I. Dutta, R. Panat, “On the Deformation Mechanisms and Electrical Behavior of Highly Stretchable Metallic Interconnects on Elastomer Substrates”, Journal of Applied Physics, Vol. 120, Issue 11, pp. 115103-1 to 11, 2016. PDF

doi: http://dx.doi.org/10.1063/1.4962453

DIC Strain Video

23. M. T. Rahman, J. McCloy, C. V. Ramana, and R. Panat, “Structure, Electrical Characteristics and High-Temperature Stability of Aerosol Jet Printed Silver Nanoparticle Films”, Journal of Applied Physics, Vol. 120, Issue 7, pp. 075305-1 to 11, 2016. PDF

doi: http://dx.doi.org/10.1063/1.4960779

22. M. T. Rahman, A. Rahimi, S. Gupta, and R. Panat, “Microscale Additive Manufacturing and Modeling of Interdigitated Capacitive Touch Sensors”, Sensors and Actuators A: Physical, Vol. 248, 94-103, 2016. PDF doi: http://dx.doi.org/10.1016/j.sna.2016.07.014

21. H. Yang, M. T. Rahman, D. Du, R. Panat, and Y. Lin, “3-D Printed Adjustable Microelectrode Arrays for Electrochemical Sensing and Biosensing”, Sensors and Actuators B: Chemical, Vol. 230, 600-606, 2016. PDF doi: http://dx.doi.org/10.1016/j.snb.2016.02.113

20. Y. Arafat, I. Dutta, R. Panat, “Super-stretchable Metallic Interconnects on Polymer with a Linear Strain of up to 100%” Applied Physics Letters, 107, 081906, 2015 PDF

doi: http://dx.doi.org/10.1063/1.4929605 Video: https://www.youtube.com/watch?v=CgbG8OHgHuU

WSU News: Researchers create stretchable metal conductors for electronics

Robot Magazine: Indium-Plastic Film Could Lead to Stretchier Skin for Robots

American Institute of Physics News: Researchers create stretchable metal conductors for electronics

Gizmodo: A New Stretchable Conductor Can Extend to Twice Its Length

Today’s Medical Developments: Stretchable metal conductors for electronics

Humanoid Magazine: A method to stretch metal without breaking it

Physics.org: Researchers create super-stretchable metallic conductors for flexible electronics

Materials Today News (Elsevier): Indium-coated plastic makes ideal conductor for flexible electronics

Space Daily: Super-stretchable metallic conductors for flexible electronics

Semiconductor Engineering Mag: Stretchy Metal

All Specs.com: Stretchable Metal Conductors May Foil Coiled Springs

Manufaturing.net: Study: New Metal Fabric Can Stretch To Double Its Original Size

Next Power Up: Scientists Create Stretchable Metal

Digital Trends: WSU scientists have developed stretchable metal, paving the way for flexible electronics

Engineering and Technology News: Stretchable metal film breakthrough expands possibilities

Chemie Europe: WSU researchers create super-stretchable metallic conductors for flexible electronics

Australian Manufacturing: US researchers create super stretchable metal conductors for flexible electronics

Science News Line: WSU Researchers Create Super-stretchable Metallic Conductors for Flexible Electronics

NanoNews on Nanowerk: Researchers create super-stretchable metallic conductors for flexible electronics

Eureka Alert: WSU researchers create super-stretchable metallic conductors for flexible electronics

Dutch Press: UITREKBAAR METAAL VOOR FLEXIBELE ELEKTRONICA

French Press: Une technique pour étirer le métal pourrait bouleverser le secteur de l’électronique

Greek Press: Ερευνητές ανακάλυψαν “ελαστικό” μέταλλο, ανοίγοντας νέους δρόμους στην κατασκευή wearables

Ukranian Press: Создана модель сверхрастяжимого металлического проводника

19. M. T. Rahman, L. Renaud, M. Renn, D. Heo, R. Panat, “Aerosol Based Direct-Write Micro-Additive Fabrication Method for Sub-mm 3-D Metal-Dielectric Structures” Journal of Micromechanics and Microengineering, Vol. 25 (10), 107002 (2015). PDF doi: http://dx.doi.org/10.1088/0960-1317/25/10/107002

18. R. Panat, “A Model for Crack Initiation in the Li-ion Battery Electrodes”, Thin Solid Films, Vol. 596, pp. 174-178 (2015). PDF doi: http://dx.doi.org/10.1016/j.tsf.2015.07.066

17. M. T. Rahman, L. Renaud, M. Renn, D. Heo, R. Panat, “3-D Antenna Structures Using Novel Direct-Write Additive Manufacturing Method”, ASME 2015 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, Paper No. IPACK2015-48187, pp. V003T03A002 (2015) Link

16. Y. Arafat, I. Dutta, R. Panat, “Highly Stretchable Interconnects for Flexible Electronics Applications” ASME 2015 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, Paper No. IPACK2015-48130, pp. V002T02A029 (2015) Link

15. Z. Song, T. Ma, R Tang, Q. Cheng, X. Wang, D. Krishnaraju, R. Panat, C. K. Chan, H. Yu, and

H. Jiang, “Origami Lithium Ion Batteries”, Nature Communications, 5:3140, 10.1038/ncomms4140,

(2014). PDF

14. R. Panat, S. Dattaguru, H. Balkan, Y. Min, H. Seh, X. Zhao, “Mechanical Reliability of

Embedding of Components in Ultra-High Performance Microprocessors”, IEEE Transactions on

Device and Materials Reliability, Vol. 4 (5), 857 (2014). PDF.

13. R. Panat, E. Parks, and J. Wang, “Effects of triboelectrostactic changing between polymer

surfaces in manufacturing and test of integrated circuit packages”, IEEE Transactions on

Components, Packaging and Manufacturing Vol. 4 (5), 943 (2014). PDF.

12. R. Panat, V. Dimitrova, S. Selvamundiany, K. Ishiko, and D. Sun, “The application of Lean Six

Sigma to the configuration control in Intel’s manufacturing R&D environment”, International

Journal of Lean Six Sigma, Vol. 5 No. 4, 444-459 (2014). PDF

Selected by the journal as a ‘Highly Commended Paper of 2014’.

11. R. Panat, “On the data and analysis of research output of India and China: India has significantly

fallen behind China”, Scientometrics (Springer), Vol. 100 (2), 471-481 (2014).PDF.

10. Y. Min, R. Olmedo, M. Hill, K. Radhakrishnan, K. Aygun, M. Kabiri-badr, R. Panat, S.

Dattaguru, and H. Balkan, “Embedded Capacitors in the Next Generation Processor”, 63rd

ECTC Conference, IEEE, 1225-1229 (2013). PDF.

9. N. Raravikar, R. Panat, and S. Jadhav, “A tombstone initiation model for small form factor

surface mount passives” IEEE Transactions on Components, Packaging and Manufacturing, Vol.

2 (9), 1486-1491 (2012).

8. Li Yan, R. Panat, R. Mulligan, P. Srinath, and A. Raman, “The application of 2D X-ray hot stage

in flip chip package failure analysis”, IEEE Transactions on Device and Materials Reliability,

Vol. 11 (1), 141-147 (2011). PDF.

7. R. Panat, K.J. Hsia and D.G. Cahill, “Evolution of surface waviness in thin films via volume and

surface diffusion”, Journal of Applied Physics, 97, 013521 (2005).PDF.

6. R. Panat, K.J. Hsia and J. Oldham, “Observation of rumpling instability in thermal barrier

systems under isothermal conditions in vacuum”, Philosophical Magazine, 85 (1), 45-64 (2005).PDF

5. R. Panat and K.J. Hsia, “Experimental investigation of the bond coat rumpling instability under

cyclic and isothermal temperature histories in thermal barrier systems,” Proceedings of the Royal

Society of London, Series A, Vol. 460, 1957-1979 (2004).PDF.

4. R. Panat, S. Zhang and K.J. Hsia, “Bond coat surface rumpling in thermal barrier coatings” Acta

Materialia, 51, 239-249 (2003).PDF.

3. S. Zhang, R. Panat and K.J. Hsia, “Influence of surface morphology on the adhesion strength of

aluminum/epoxy interfaces”, Journal of Adhesion Science and Technology, 17 (12), 1685-1711

(2003). PDF

2. R. Panat, K. Jakus, J.E. Ritter and P. Shah, “Erosion and strength degradation of an elastic

modulus graded alumina-glass composite,” Ceramic Engineering and Science Proceedings, 21, 3

(2000) 635. PDF

1. J.E. Ritter, K. Jakus, R. Panat, “Impact damage and strength degradation of fused silica,” MRS

Symposium Proceedings, 531 (1998) 53. Link

Intellectual Property

- Panat R. and Jaiswal B., “Nanowires coated on traces in electronic devices”, patent Issued P41087US, WO2013095663 (2016). Link PDF

- R. Panat and L. Lei, “Low-cost fiber optic sensor for large strain”, Patent Filed (April 2016) Link

- R. Panat, “Additive manufacturing of porous scaffold structures”, Patent Filed (Nov 2015). Link

- R. Panat and D. Heo, “Three dimensional passive components”, Patent Filed (Nov 2015). Link

- R. Panat and D. Heo, “Three dimensional sub-mm wavelength sub-THz frequency antennas on flexible and in-situ cured dielectric using printed metal structures”, Patent Filed (Nov 2015). Link

- I. Dutta and R. Panat,” Highly stretchable interconnect devices and systems”, Patent Filed (Sept 2015). Link

- Raravikar N. and Panat R., “Nanolithographic method of manufacturing an embedded passive device for a microelectronic application, and microelectronic device containing the same”, US Patent 8068328 (2014). Link