Flexible/Stretchable Electronics

WSU’s Advanced Manufacturing Lab focuses on interdisciplinary research that combines mechanical, materials and electrical engineering with an aim to follow up with latest commercial requirements. The industry has seen its fair share of rigid electronics research but has limited applications for flexibility. That’s why one of our key objectives is to engineer a seamless combination of materials for interconnects that are bendable and stretchable beyond their limits compared to the bulk counterparts while maintaining the mechanical and electrical integrity.

That’s why one of our key objectives is to engineer a seamless combination of materials for interconnects that are bendable and stretchable beyond their limits compared to the bulk counterparts while maintaining the mechanical and electrical integrity.

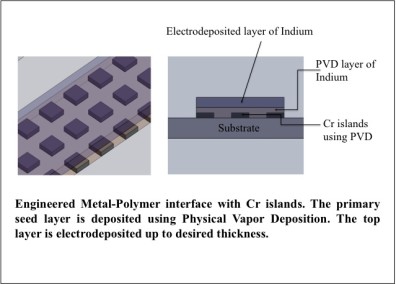

The choice of metals and supporting substrates for the system is driven by industrial needs (i.e., cost effective and highly deformable). While metal delamination from the substrate (i.e., Polymers) is a known phenomenon that arises from the mismatch of two different types of materials, our research is aimed to address this issue along with other obvious ones such as permanent increase in resistance and resistivity.

The choice of metals and supporting substrates for the system is driven by industrial needs (i.e., cost effective and highly deformable). While metal delamination from the substrate (i.e., Polymers) is a known phenomenon that arises from the mismatch of two different types of materials, our research is aimed to address this issue along with other obvious ones such as permanent increase in resistance and resistivity.

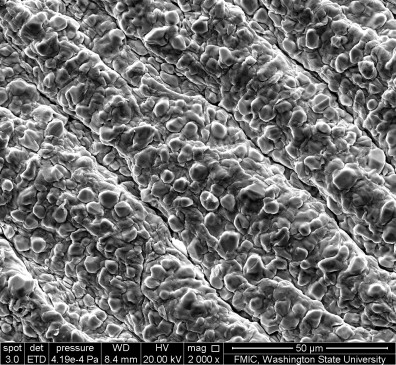

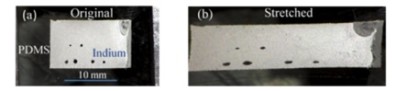

Since the physics behind the extreme stretch-ability of thin metal films on polymer substrates needs immense research efforts, we aim to hypothesize the mechanism relating to our experimental results. Our success in achieving up to 100% linear strain on metal films on flexible substrates has been a major driving factor towards expanding the research to tune up the system for manufacturing prototypes of flexible interconnects to fulfill industry standards in near future. The interface of the system has been designed in such a way that this huge amount of strain does not give significant raise in metal resistivity. Engineering crack formation in the adhesion layer towards large strain accommodation of conducting metal layer has been a major part in correlating hypothesized mechanism with in-situ experimental results.

success in achieving up to 100% linear strain on metal films on flexible substrates has been a major driving factor towards expanding the research to tune up the system for manufacturing prototypes of flexible interconnects to fulfill industry standards in near future. The interface of the system has been designed in such a way that this huge amount of strain does not give significant raise in metal resistivity. Engineering crack formation in the adhesion layer towards large strain accommodation of conducting metal layer has been a major part in correlating hypothesized mechanism with in-situ experimental results.

Our success in recent results has been picked up by different media all around the world. Here are some of the links-

WSU News: Researchers create stretchable metal conductors for electronics

Physics.org: Researchers create super-stretchable metallic conductors for flexible electronics

Robot Magazine: Indium-Plastic Film Could Lead to Stretchier Skin for Robots

Space Daily: Super-stretchable metallic conductors for flexible electronics

Gizmodo: A New Stretchable Conductor Can Extend to Twice Its Length

Semiconductor Engineering Mag: Stretchy Metal

All Specs.com: Stretchable Metal Conductors May Foil Coiled Springs

Manufaturing.net: Study: New Metal Fabric Can Stretch To Double Its Original Size

Digital Trends: WSU scientists have developed stretchable metal, paving the way for flexible electronics

Engineering and Technology News: Stretchable metal film breakthrough expands possibilities

Chemie Europe: WSU researchers create super-stretchable metallic conductors for flexible electronics

Australian Manufacturing: US researchers create super stretchable metal conductors for flexible electronics

Science News Line: WSU Researchers Create Super-stretchable Metallic Conductors for Flexible Electronics

NanoNews on Nanowerk: Researchers create super-stretchable metallic conductors for flexible electronics

Eureka Alert: WSU researchers create super-stretchable metallic conductors for flexible electronics

Dutch Press: UITREKBAAR METAAL VOOR FLEXIBELE ELEKTRONICA

Greek Press: Ερευνητές ανακάλυψαν “ελαστικό” μέταλλο, ανοίγοντας νέους δρόμους στην κατασκευή wearables

Ukranian Press: Создана модель сверхрастяжимого металлического проводника

Youtube Video on Stretching the system– https://www.youtube.com/watch?v=CgbG8OHgHuU

Publications:

Y. Arafat, I. Dutta, R. Panat, “Super-stretchable Metallic Interconnects on Polymer with a Linear Strain of up to 100%” Applied Physics Letters, 107, 081906, 2015 PDF

Y. Arafat, I. Dutta, R. Panat, “On the Deformation Mechanisms and Electrical Behavior of Highly Stretchable Metallic Interconnects on Elastomer Substrates”, Journal of Applied Physics, Vol. 120, Issue 11, pp. 115103-1 to 11, 2016. PDF

doi: http://dx.doi.org/10.1063/1.4962453